| THERMAL EXPANSION | |||

| COEFFICIENT OF LINEAR THERMAL EXPANSION/CONTRACTION FOR COMMONLY USED PLASTIC AND METAL PIPING MATERIALS | |||

| Piping Material | Coefficient of linear Thermal Expansion (cm/cmx°C) | Resultant Pipe Expansion (cms/100 meter X °C) | Expansion as compared to Copper |

|---|---|---|---|

| Cast Iron | 10.6X10^-6 | 0.11 | 0.65 |

| Steel | 12.1X10^-6 | 0.12 | 0.71 |

| Copper | 16.9X10^-6 | 0.17 | 1.00 |

| KiTEC CPS | 23.4X10^-6 | 0.23 | 1.35 |

| CPVC | 610.0X10^-6 | 0.61 | 3.59 |

| PP | 760.0X10^-6 | 0.76 | 4.47 |

| PEX | 171.0X10^-6 | 1.71 | 10.06 |

Background

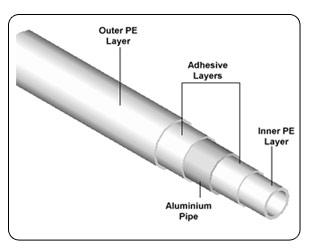

KiTEC INDUSTRIES (INDIA) PVT. LTD., an ISO 9001:2015 company, is a joint venture promoted to manufacture revolutionary piping system popularly known as "KiTEC Composite Pipes". The company commenced its manufacturing operation in technical and financial collaboration with KiTECHNOLOGY BV, Netherlands at its State of art manufacturing facility in Silvassa (India) in October, 1996. The past few decades account for accelerating the trend towards the use of technologically superior alternative materials, particularly plastics and ceramics based, as replacement for metals including steel and non-ferrous materials (Copper, aluminum and brass). In India, GI pipes were being extensively used for domestic water distribution system. However, this trend has changed and use of alternative materials is being already thought of.

KiTEC is a brand that was earlier registered as trade mark of KiTECHNOLOGY BV, Netherlands. The Company got the trade mark with manufacturing license and the company promoted the brand for various fluid, air and gas conveying small dia pipe system. In 2008 the trade mark was transferred to the Company for India. From a small range of three sizes that is ½”, ¾” and 1” The Company has enhanced the technology with own R&D efforts up to 4”. Perhaps KiTEC is the only Company who manufactures composite pipes in 3.5” and 4” size. In India today KiTEC has become synonym to Composite pipes.

Milestones

There are many mile stones that the Company has achieved - almost all work is in manufacture of composite pipes and jointing techniques. Considering the cost aspects KiTEC first developed fittings in engineering plastics instead of brass as the brass fittings were very costly. Subsequently introduced DZR brass fittings as plain brass had its own issues. KiTEC also developed crimp fittings and push fit fittings. Considering cost aspects and application range for pipes 5063 to 90110, the Company developed the fittings in SS in these sizes. In pipe manufacture the Company developed the design for die to manufacture 1.25”, 1.5”, 2” pipes. KiTEC then moved to higher sizes with different process. Here the manufacturing process as well as welding technology differed. The Company has also developed the process to manufacture pre-insulated composite pipe perhaps for the first time in world. There are more development in PVC SWR pipes such as PVC silent pipes, PVC SWR pipes with carbon black for higher UV stability and range of PVC fittings for silent pipes. Chronology of various mile stones is as below:

Brass Push Fit Fittings developed for sizes 1216 to 2025

Ministry of Science & Technology has recognized KiTEC as in house R&D Unit in the year 2017.

IAPMO India has recognized the KiTEC for in-house testing facilities since 2015.

KiTEC started manufacturing pipes as per IAPMO IGC -India 308 and IGC-India 309 from 2014.

IAPMO IGC-India 308 and IGC-India 309 standard for PE-AL-PE and PE-AL-PEX pipes were formulated in the year 2014.

Started production of PEX-AL-PEX Composite Pipes as per ASTM F 1281.

Production of 5063, 6375, 7590 and 90110 KiTEC Composite Pipes commenced in 2008.

Added 4050 KiTEC Composite pipes in 2006

Introduced indigenously developed Brass Crimp Type Internal Sealing Fittings in 2005.

Introduced KiTEC Composite PR RT Pipes to cater Industrial applications with higher temperature requirements.

Introduced indigeniously developed Composite Crimp Internal Sealing Fittings in 2003.

Considering the market demand introduced KiTEC Composite Plumbing System in 2003.

Introduced 1014 KiTEC Composite pipes in 2003.

Included 2532 KiTEC Composite pipes in product range in 1998 and 3240 KiTEC Composite Pipe in 1999.

Introduced indigenously developed Composite Compression Internal Sealing Fittings in 1996.

Commenced production in 1996 with size range 1216, 1620 and 2025 KiTEC Composite Pipes.

Seed marketing started in 1994 for 1216, 1620 and 2025 KiTEC Composite pipes with Brass Compression type internal seal fittings.

Quality

KITEC brand is known for its quality and innovation. Hence when The Company introduces the new products, customers value the innovation. The Company is not operating in a large market segment but have limited market segment and happy to service that market very diligently. This gives much more word of mouth publicity.

The Company’s driving philosophy is based on:

-

Customer Focus: KiTEC philosophy if to offer technically correct products to the customer for required application i.e. understanding the customer’s requirement and suggest right product. No big talks. In case the products does not meet the customer’s requirement the product is not offered.

-

Quality: KiTEC Products have gained confidence of the customers for their utmost quality.

-

Continuous improvement: The Company has setup R&D center for continuous improvement of the products. The Ministry of Science and Technology, Government of India has accorded recognition to the in-house R&D center.

-

Pre-sales and post sales service: Designing piping layouts, training to plumbers, testing on-site etc. are regular features in KiTEC marketing map.

-

Ethical Business practices: The Company practices of fair business policies and practices regarding potentially controversial issues - such as corporate governance, discrimination, fiduciary responsibilities, and environment.

-

Integrated Management System: KiTEC has well defined Integrated Management System and the same is as below:

KiTEC is committed to satisfying all statutory, legal and compliance obligations relating to the environment, health and safety. We are committed to continuous improvement of our IMS processes and performance. We strive to enhance customer satisfaction and maintain a leading position in Indian Market.

KiTEC Management team establishes, implements and maintains IMS Policy that:

-

is appropriate for its purpose, size, for context of the organization and supports its strategic direction, including the nature, scale and environmental impacts of its activities, products and services and to the specific nature of its OH&S risks and OH&S opportunities;

-

provides a framework for setting and reviewing the IMS objectives;

-

Within The IMS Policy, Management team is committed to:

-

satisfy applicable requirements related to IMS and to maintain the effectiveness of IMS; satisfy applicable regulatory requirements;

-

fulfil all applicable legal requirements and other requirements which relating OH&S hazards and identified environmental aspects; the protection of the environment, including prevention of pollution and other specific commitment relevant to the context of the organization (for example sustainable resource use);

-

provide safe and healthy working conditions for the prevention of work-related injury and ill health;

-

eliminate hazards and reduce OH&S risks;

-

continual improvement of the IMS performance;

-

fulfil its compliance obligations;

-

consultation and participation of workers for Safety and Occupational Health and Safety;

The IMS Policy also includes Corporate Social Responsibility (CSR) Policies. Management team, through its CSR Policies, declares its commitment to the fight against bribery and corruption, unethical behavior and all-round non-discrimination. An Ethics Escalation Policy: „Whistle-Blowing Policy will include:

We shall not tolerate bribery and corruption in any form and at all levels without exception.

-

We undertake to review, report and deal with corruption in any manifestation of corruption, in accordance with the law.

-

We shall not cooperate with partners who have been proven to be corrupt or corrupt another form of unethical behavior.

-

We exclude discrimination against our workers and other stakeholders based on gender, race, belief, orientation, and other relevant factors.

-

We are committed to creating a work environment with the greatest emphasis on social background, safety and ergonomics, mental balance.

-

Management Team is always open to any communication and properly investigates all received suggestions.

The IMS Policy is available and maintained as documented information; communicated, understood and applied within the organization; and also available to relevant interested parties; reviewed for ensuring its validity and continuous suitability. Policies for various components of IMS are given below:

Quality Policy

We at KiTEC INDUSTRIES (INDIA) PRIVATE LIMITED manufacturer of Composite (Polymer – Aluminium- Polymer) /HDPE / UPVC pipes and fittings and Pre-insulated composite Pipes (Polymer- Aluminium – Polymer with Insulation).

We are committed to meet the requirements of customers - Internal and External with respect to Quality of our products and services.

We shall concentrate on preventive methods and adopt an innovative approach to make Total Quality a way of life with an objective to “Do It Right, the first time”. We shall focus on continual improvements in all areas of our business.

We shall create an environment in the organisation that will encourage the employees and suppliers to eliminate the non-conformances to generate error free output and to improve Quality of our products and services.

We are committed to comply with the requirements of ISO 9001:2015 standards, including the statutory and regulatory requirements.

Environmental Policy

KiTEC INDUSTRIES (INDIA) PRIVATE LIMITED is committed to protecting the environment, the health and safety of our employees, and the community in which we conduct our business. It is our policy to seek continual improvement throughout our business operations, to lessen impact on the local and global environment by conserving energy, water and other natural resources; reducing waste generation; recycling and; reducing use of toxic materials. We are committed to environmental excellence and pollution prevention, meeting or exceeding all environmental regulatory requirements, and to purchasing products, which have greater recycled content with lower toxicity and packaging, that reduce the use of natural resources.

Pioneering many products in India

Being the pioneer of Multilayer Pipes in India since 1996, KiTEC has developed additional sizes from 2025 (25 mm OD) in the initial period to 90110 (110 mm OD) size now and also developed many changes in jointing techniques to meet the requirement of the market. The excellence in quality and long service life of KiTEC-CPS has been widely acclaimed in India and the Pipes are now widely applied in fields of potable water system, compressed air system, gas distribution system and host of other applications in small diameter piping systems.

KiTEC pipe uses special polyethylene grade which is hygienic, non- toxic and smooth. The middle aluminium layer is impermeable. The structure provides KiTEC pipe the advantage of both metal and plastic while avoiding all the weaknesses associated with these materials.

The KiTEC manufacturing process ensures that the KiTEC Multilayer pipe is a green product. The materials used in the process are a specific grade of aluminium, polymer based adhesive and polyethylene resins. The aluminium used in the pipes is recycled from scrap aluminium. The polyethylene can be melted and separated from aluminium. Both aluminium as well as polyethylene used in KiTEC Pipes are recyclable. The manufacturing process uses electrical power, compressed air and cooling water. The process does not give rise to pollution, nor does it have any adverse impact on environment. Waste and scrap materials are disposed of by traditional methods. Cooling water used in the process is circulated in closed loop and not wasted.

The facility is supported by an advanced R&D Centre. Our R&D team has developed its own technology to produce pipes in sizes that are not the standard sizes available in the market.

KiTEC also provides compatible series of fittings and tools. These smartly designed components lend KiTEC piping system high flexibility, adaptable in many environments meeting every need of the customer.

As an innovative approach, KiTEC introduced for the first time in the world PVC Pipes and fittings in jet black colour with carbon black and few more additives as UV stabilizer. The Company also developed PVC silent pipes for drainage application with suitable fittings.

The unique Flute Wall Construction protects the inner core layer from external factors. This unique Flute Wall Construction traps the sounds that occur in the pipes, and notably reduces noise in the pipe system.

KiTEC Silent is a system of pipes that is specially designed to reduce the noise that accompanies the evacuation of wastewater and rainwater, and also decrease the sounds that often occur when substances travel through sanitary pipes.

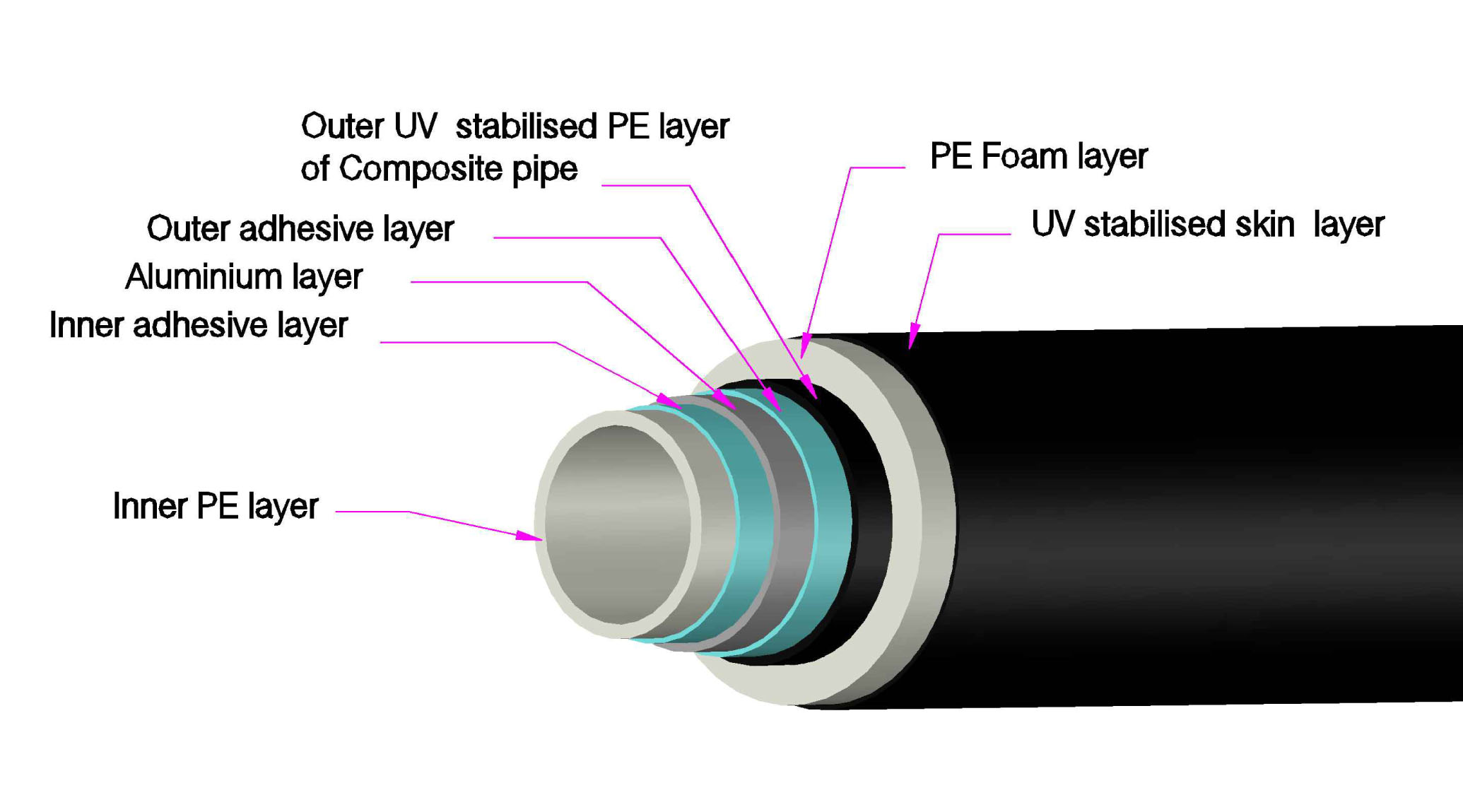

As it is KiTEC philosophy to offer technically correct products to the customer, KiTEC has developed a Pre-insulated Composite Pipe to reduce the heat loss.

The Pre-insulated KiTEC Composite Pipes has been developed to meet the demanding standards of commercial hot and cold water reticulating systems.

With excellent thermal insulation performance, Pre-insulated KiTEC Composite Pipes provides the energy retention properties required by current specifications

One more unique development by KiTEC R&D team is design and manufacture of Multi floor Trap.

If you smell a noxious sewer-like odor inside your home, chances are it is sewer gas escaping from the drainage system. Sewer gas not only smells gross, the methane and bacteria it contains can be dangerous to your health, causing headaches or even more serious ailments. Even scarier, high concentrations of methane gas are combustible, which can cause an explosion. If you notice this distinctive foul odor, do not ignore it.

Sewer gas is typically restricted from entering buildings through plumbing traps that create a water seal at potential points of entry.

KiTEC , India's first and the largest manufacturer of Multilayer Composite Pipes has now developed a Multi Floor Trap which collects and discharges the waste water to drain line and also acts as a safety barrier avoiding harmful gases to enter the room.

UNIQUE FEATURES OF KITEC MULTI FLOOR TRAP

- Suitable for all types of drainage installations

- Easy to open and fit.

- Elegant look.

- Full bore outlet and three optional inlets.

- Has 63 mm water seal.

- Trap with flap and air tight cleaning eye.

- Leak proof jointing due to positive compression fitting with internal sealing

KiTEC piping system has taken the plumbing world by storm offering unique performance and Installation features beyond the reach of traditional piping materials. KiTEC backs its plumbing systems with the very best customer service through its network of Marketing Associates all over the country.

Distinguishing Features

Some of the distinguishing features of KiTEC Composite Pipes are as follows:

-

Thermal Strength properties of KiTEC pipe are balanced to satisfying levels. (To show the bar at different temperatures) At ambient temperature, copper pipe with tin-lead solder joint and KiTEC pipe are pressure rated at 14 bar. Polyethylene pipe of same wall thickness as KiTEC is having rated pressure of 10 bar. When the temperature increases to 60 degrees Centigrade, the pressure rating for KiTEC and copper drops down to 11 bar. In case of Polyethylene pipe, it is only 3 bar. At 80 degrees Centigrade, the pressure for copper comes down to 7 bar and for KiTEC, to 6 bar. Polyethylene pipes are not used for pressure applications at this temperature.

-

KiTEC pipe undergoes, nearly, the same thermal expansion as that of copper pipe

-

Thermal Conductivity of KiTEC Composite pipe is O.43 Watt/[m ºk.]. In case of hot water piping the insulation requirement is only 5O% of the same required for conventional metal pipes. In case of concealed hot water piping, insulation is not essential.

-

Avoid condensation: KiTEC composite pipes provide an increased resistance to the onset of condensation or pipe sweating. In air conditioning application. Metal pipe in the same situation will condense moisture on the outside pipe surface or sweat far sooner than KiTEC. For given internal fluid temperature and relative humidity metal pipe sweats much before any size of KiTEC Composite Pipe.

KiTEC PIPE APPLICATIONS

-

Hot and cold water plumbing and water supply

For hot water, no insulation is required in concealed installation. In case of external piping, the insulation requirement is 50% less than that of conventional metal pipes. KiTEC pipe can be used safely for temperature up to 80°C at recommended pressure rating in plumbing and no special care is required to be taken at the time of installation. KiTEC pipes are having very low Linear Co-efficient of thermal expansion.

* Solar Heating * Hot and Cold Water System * Jet Pump Piping * Submersible Pump Delivery -

Air Conditioning

Installation of KiTEC piping system is easy and fast. It is easier to work with KiTEC Piping system particularly when the piping is required to be inside the tight space which is generally encountered in case of piping for air conditioning. With very low thermal conductivity, KiTEC pipe needs very less insulation for the protection against condensation. Pre-insulated flexible KiTEC pipe provides the best solution for piping in air conditioning system.

* Refrigerant Systems * Air Conditioning. -

Chemical Handling

KiTEC Piping System offers, perhaps, the best chemical and corrosion resistance as compared to any plastic used in the manufacture of pipes. PE is renowned for its toughness, long service life and resistance to deterioration in the most extreme environments. In addition to this, with aluminium layer KiTEC piping system resists the swelling of system against liquid hydrocarbons such as diesel, petrol, kerosene and fuel oils.

Food and Chemical Processing * Fuel Oil Lines * Insecticides Spraying. -

Cable Conduits

KiTEC composite pipes are very effective as conduit, especially for high speed data transmission, telecommunication and signal cables. Its uniqueness is in its three layer construction, incorporating a welded sealed aluminium tube providing the very latest method of EMI screening covered both internally and externally with a layer of Polyethylene. This gives the product comparable strength to that of a metal conduit with the flexibility of a plastic conduit.

*Electrical and Telecommunication Conduits. -

Compressed Air and Gaseous Fluids

KiTEC pipe is totally corrosion resistant. Compression joints provided in KiTEC piping system are leak proof when used for gaseous fluids. Moisture content in compressed air lines will never have any adverse effect on any of the components of KiTEC piping system.

* Natural Gas Distribution * Compressed Air Systems. -

Other Applications

* Vacuum Systems * Radiator Central Heating * Under Floor Heating.

Products From International Manufacturers

In continuation of its efforts to market technologically different products, KiTEC also markets from international manufacturers:

-

KiTEC started marketing the “THE ADVANCED CRYSTALLISATION PROCESS - (ACP)TM: It is advanced technology with a proven record of scale control and corrosion protection. The ACP is technology driven and has been developed over many years by the team of Chemists and Engineers at Advanced Hydro Ltd. in the UK.

-

KiTEC Thermostatic Mixing Valve ensures that cold water mixes with the hot water to provide water at the set temperature. The auto shut-off feature stops the flow of water in the event of a hot or cold supply failure to prevent scalding or thermal shock.

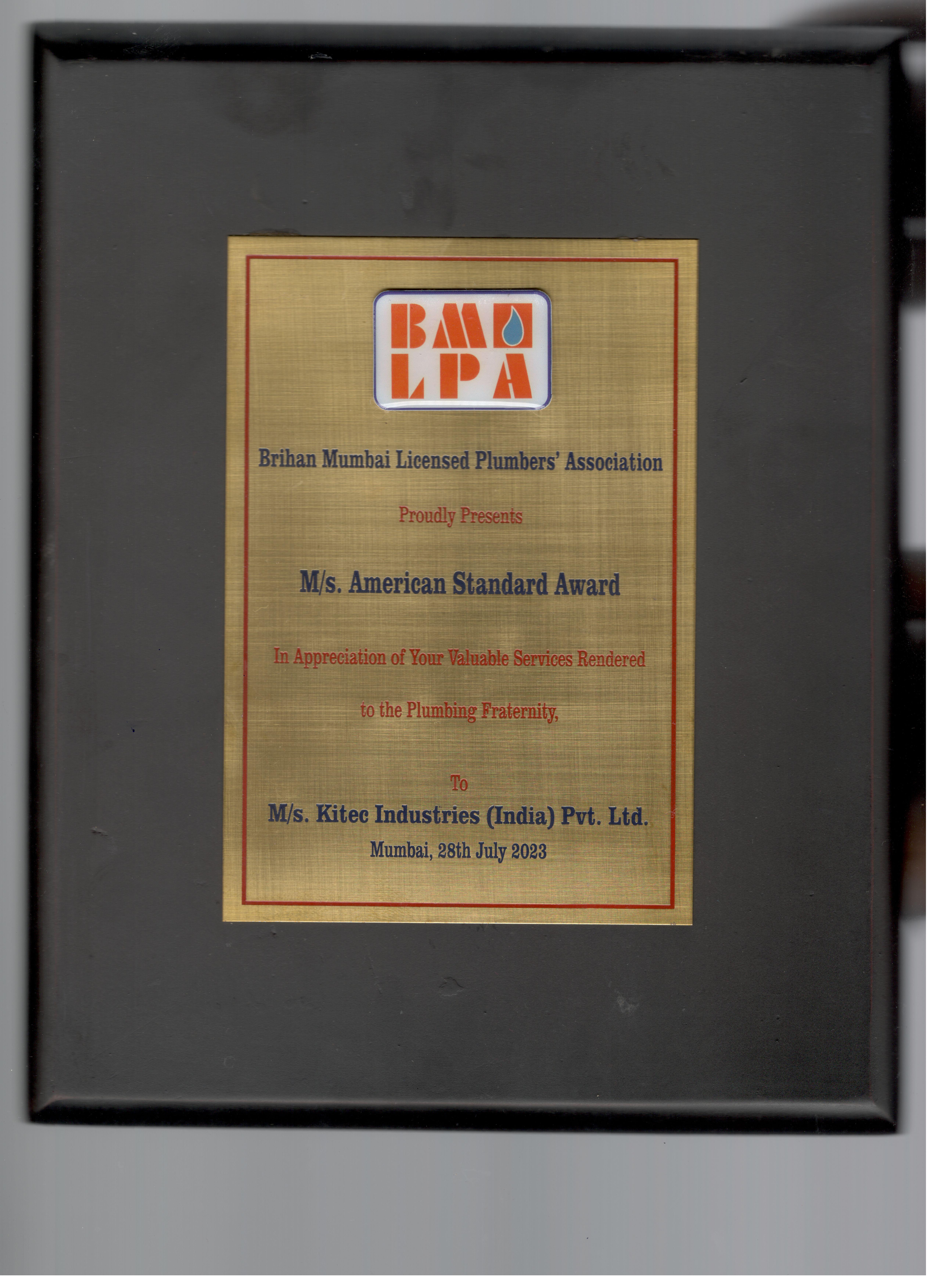

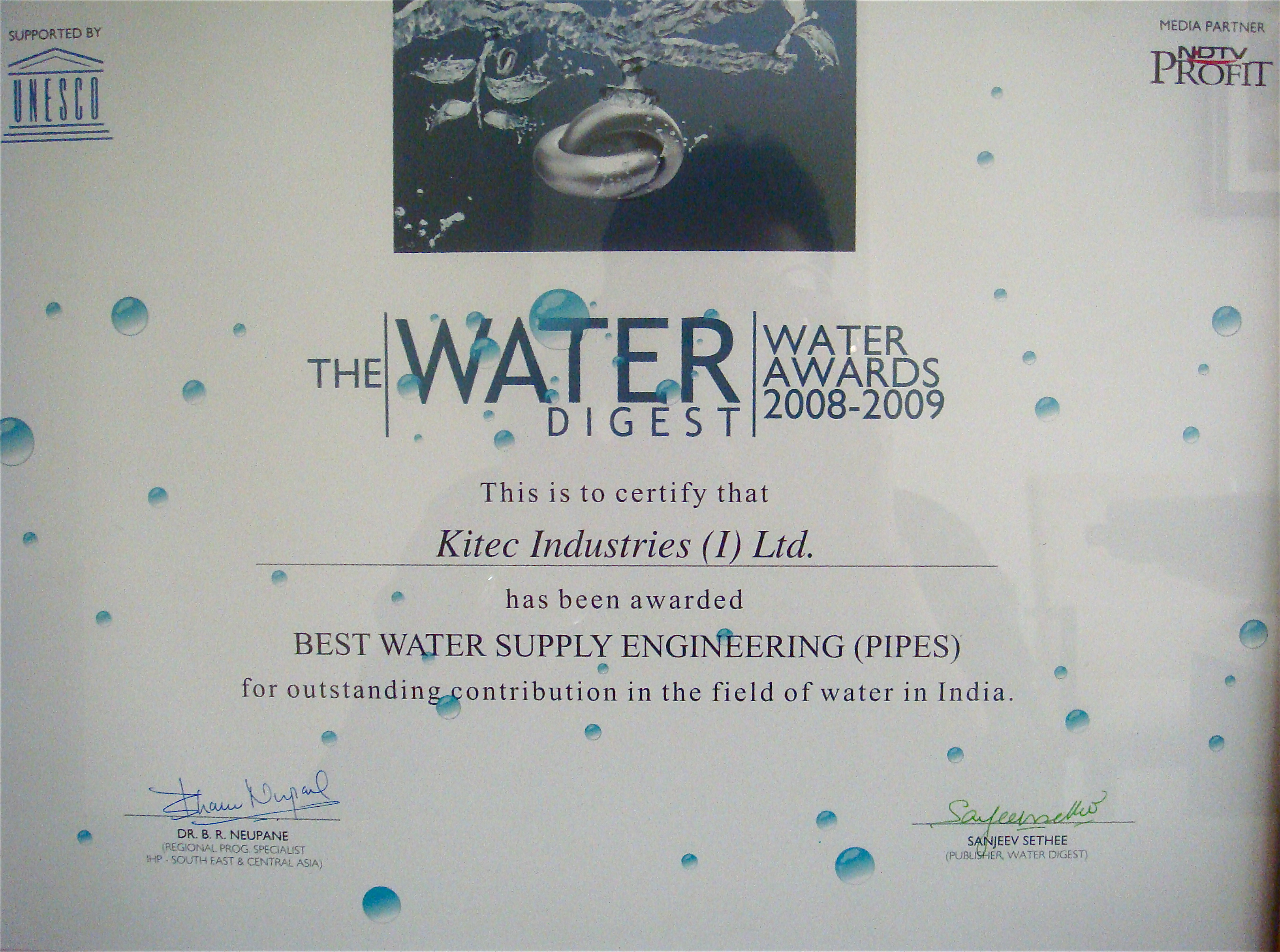

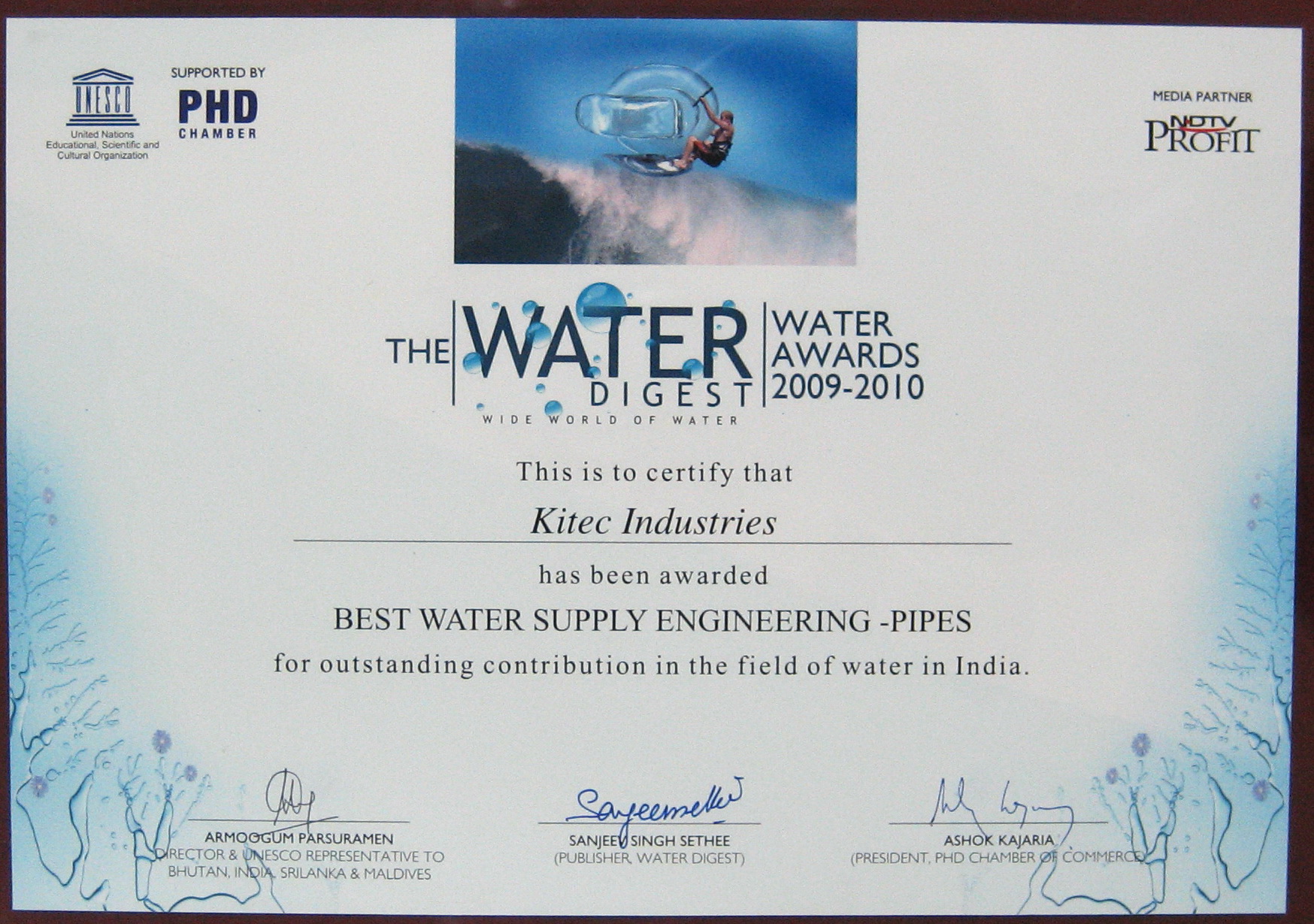

Recognition

Because of its revolutionary work in Piping, KiTEC has been conferred several prestigious awards, viz:

Why KiTEC?

Water supply piping is one of the most important constituents of the building. Various piping materials are used for building water supply piping. These can be categorized as- I. Metal pipes and II. Plastic pipes. Following piping materials are used in these categories:

- Metal Pipes : GI Pipes, Copper Pipes.

- Plastic Pipes : PVC pipes, CPVC pipes, PE pipes, XLPE pipes, Polybutylene Pipe

- Composite pipes : Metal & Plastic combination is the new addition

Metal and plastic pipes have their own advantages. However, there are some inherent disadvantages associated with both types of the pipes. Hence the innovation of Composite pipes – that eliminates all the disadvantages of both the materials and takes advantage and strengths of both the materials.

Given below are various properties and performance requirements for sound plumbing. The performance characteristics for various associated factors are as follows:

1. Effect of water Quality

The pipes must be suitable for use with hard as well as soft water.

Metal pipes are generally susceptible to corrosion. Copper pipes are also prone to corrosion when used for soft acidic water. In case of hard water, scale deposition in GI pipes leads to unsatisfactory flow over the life span of the pipe. In many cases, the pipe has to be replaced frequently.

Plastic pipes have no effect of water quality.

Composite pipes, with inner and outer plastic (PE) layer, have no effect of water quality and are suitable for hard as well as soft water.

2. Health Criterion

The effect of water on the piping material is a major factor that many times goes neglected. The basic piping material, many a times, has some effect or their on the pipe. This can be tested for following properties:

- Taste of water.

- Appearance of water

- Growth of aquatic micro-organisms.

- Extraction of substances that may be of concern to public health.

Because of corrosion, metal pipes, particularly GI pipes, cannot be considered good on this ground. The lead content in GI further reduces the suitability for this application. In case of copper pipes solder joints and fluxes have lead content that causes worries to scientists.

Plastic pipes as well as composite pipes do not have any adverse effect of water.

3. Thermal Strength properties

The piping material, ideally, should not have any limitations when used for hot water.

Metal pipes, GI as well as copper, do not have any effect when used for hot water.

In plastic pipes, the rated pressure of pipe reduces drastically with increase in design life span at specified operating temperature. At the same time, the life of the pipe reduces drastically with the increase in operating temperature.

Thus PVC pipes are not recommended for hot water. PE pipes also loose considerable strength when used for hot water. CPVC pipes have better strength at elevated temperature amongst all plastic pipes.

Composite pipes have these properties balanced to satisfying levels.

4. UV Resistance

Effect of UV radiation is a major criterion particularly in case of plastic pipes. Metal pipes do not have any effect of UV radiation.

PVC pipes are not supposed to be used for external piping due to the effect of UV rays.

CPVC contains TiO2, which is not as good a UV stabilizer as carbon black. Hence, these pipes cannot be recommended for outdoor installations. Painting of pipes for UV resistance is recommended but cannot be considered as fool proof method for UV stabilization over a long, maintenance free life span.

However, PE as well as Composite pipes does not have any effect of UV radiation if a proper UV stabilizer, such as carbon black is used. With the use of carbon black, PE pipes as well as composite pipes can be safely used for external installations.

5. Thermal Expansion

High coefficient of thermal expansion leads to thermal stresses. These stresses lead to unwanted stresses on supports provided for the piping. Thus, in case of concealed piping,

thermal stresses may lead to cracking of the tiles if the pipes with high thermal expansion coefficient are used. In case of hot water, the amount of thermal stresses developed is further higher.

Metal pipes, copper as well as GI have very low coefficient of thermal expansion. CPVC, HDPE, PVC pipes are having high coefficient of thermal expansion.

Composite pipes, because of aluminium layer, have coefficient of thermal expansion approximately equivalent to copper pipes.

Comparative values for thermal expansion for CPVC, HDPE and Composite pipes are as follows:

Coefficient of Linear Expansion:

- Composite pipes: 2.3 x 10^-5 meter/meter / oC

- CPVC: 6.1 x 10^-5 meter/meter/ oC

- HDPE: 21.6 x 10^-5 meter/meter/ oC

Composite pipe has a low coefficient of linear expansion, similar to copper tubing, and is far superior to alternate plastic pipe such as CPVC/HDPE/PP. This eliminates the need of installation "offsets" and the concern about abrading pipe due to constant movement as a result of temperature changes. Straight runs are always attainable with Composite pipe.

Example:

- 100 meter of Composite pipe with a 36oF (20o Centigrade) rise in temperature will expand 4.6 cms.

- 100 meter of CPVC pipe expands 12.2 cms. in the same situation.

- 100 meter of HDPE pipe expands 43.2 cms. in the same situation.

Freezing of water at sub-zero temperature leads to failure of rigid pipes. Hence, most of the metal pipes are not recommended to be used at sub-zero temperature. Copper pipes also cannot withstand multiple freezing cycles.

PVC and CPVC pipes are also rigid and not recommended to be used for sub-zero temperature.

PE pipes, being flexible, do not have any effect of multiple freezing cycles.

Composite pipes, when tested for multiple freezing cycles at following parameters, have passed the test for stipulated 5 cycles.

Internal pressure :10 bar.

Temperature : Ranging from -5 to –40 deg. c.

Minimum duration for sub-zero temperature 18 hours.

7. Ease in installation:

This property is generally governed by type of joints and time required for jointing, flexibility of the pipe and allowable bending radius, ease in handling (light weight) and availability of pipe lengths.

7.1 Type of joints:

GI pipes are always used with threaded joints. These joints may lead to failure over the time period because of corrosion. Failure of joint due to faulty jointing can also not be ruled out.

Copper pipes are safer, in case of solder as well as ferule joints. However solder joint cannot be done at the place of installation, particularly in case of concealed piping. Hence, the piping has to be completed outside and then fitted in the wall. In such cases, addition of a fitting or maintenance of piping becomes very difficult.

PVC pipes can be joined by solvent cement, which is quite easy. However the time required for jointing is quite high if the jointing quality is required to be good. Threaded PVC pipes carry the same disadvantages as GI pipes.

CPVC pipes are joined by solvent cement Jointing.

Shelf life of solvent cement is an area where precautions are necessary to avoid the use of ‘expired’ solvent cement as it is having shelf life less than 6 months.

PE pipes, with butt fusion joint carry the same disadvantages as soldered copper pipes.

Composite pipes are generally joined by compression fittings. Ease in achieving closer manufacturing tolerances facilitates the use of compression fittings. These joints are very easy, fast as well as safe against leakages.

7.2 Flexibility of pipe and allowable bending radius:

GI, CPVC and PVC pipes are rigid and hence cannot be bent. Use of elbows is essential. This leads to increase in number of joints and preparation of the ends for elbows in case of threaded joints, which ultimately leads to higher installation time.

Copper pipes can be bent with mechanical benders. PE pipes can be bent to a radius of 25 times the diameter of the pipe. However, due to spring back property bent pipe is required to be rigidly clamped to keep the pipe in position.

Composite pipes can be safely bent by hand when used with protective support springs to a radius of 5 times the diameter of pipe. This facilitates the elimination of elbow joints at most of the places. Composite pipe has a unique property of “Stays in shape”. Once the pipe is bent it will remain in the same form without any spring back.

7.3 Ease in handling and availability of pipe lengths:

GI as well as copper pipes are comparatively heavier and hence handling is more difficult as compared to light weight PVC, CPVC, PE and composite pipes.

GI, CPVC and PVC pipes are available in standard straight lengths. This leads to wastages as well as/or increase in number of joints.

PE and Composite pipes are available in straight as well as coil lengths up to 100 meters and above. This facilitates easier handling as well as lesser number of joints with no wastage, with properly planned piping installation.

8. Flow properties for friction loss

Pipe internal surface finish directly governs the flow properties of the pipe. GI pipe, because of rough surface have very poor flow properties.

Flow properties of copper, PVC, CPVC, PE and Composite pipes are more or less same.

9. Permeability

Air ingress can cause rapid corrosion of metallic components of plumbing system. In case of metal pipes, ingress can be via improperly made joints.

Plastic pipes are permeable to oxygen from air, thus providing a path for oxygen into the system water causing increase in corrosion. Tests on commercially available plastic pipes have shown that the permeability to oxygen is sufficiently high to promote unacceptable corrosion of components in internal plumbing system.

KiTEC Composite pipe with aluminium barrier layer would appear to be best option as an alternative to other plastic pipes to reduce the corrosion of system components caused because of permeability of pipe.

Right solution for every application

- Plumbing - Hot & cold

- Diesel/petrol/Kerosene

- Air Conditioning

- Fuel Oil Lines

- Solar Heating

- Cable Conduits

- Submersible Pump Piping

- Compressed Air Systems

- Jet Pump Piping

- Natural Gas Distribution

- Refrigerant Systems

- Food/Chemical Processing

- Radiator Central Heating

- Vacuum Systems

- Under Floor Heating

- Insecties High Pressure Flexible Composite Pipe Systems

worldwide standards and approvals

India India | IS 15450:2004 |

|---|---|

Israel Israel | Si2242 |

Australia Australia | As 4176 |

Republic of China Republic of China | CJ/T 1081999 |

Switzerland Switzerland | SVGW (SGWA) 8111112-1118 |

Germany Germany | DVGW W 542 & W 534 |

United States of America United States of America |

ASTM 1281 - F ASTM 1282 - F |

Taiwan Taiwan | CMS 12876 / K3098 CNS 12877 / K6987 |

Canada Canada | CSAB 137.9 CSAB 137.10 NSF 61 |

.png) United Kingdom United Kingdom

|

BS 7291 BS 6920 BBA Certificate No. 89/2330 WBAS Listing Nos. 8911 049 and 8911050 British Gas Standards W/92/1 |

|

|

SVGW (SGWA) 18112-1118 |

Finland

Finland Netherland

Netherland Denmark

Denmark Norway

Norway Slovakia

Slovakia Poland

Poland Portugal

Portugal Austria

Austria France

France Hungary

Hungary Romania

Romania