For jointing of KiTEC pipes, the end preparation of pipe is very important. Use KiTEC Tools only for perfect end preparation. the details are as follows:

Cutting of Pipe

Always use KiTEC pipe cutter to ensure burr free cutting. It is necessary that the cut is always at the right angle. Hold the pipe as shown in the figure to ensure right angle cut.

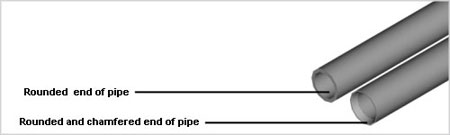

Rounding of Pipe

Push the pipe over the rounding tool, as shown. Rounding of the pipe end is essential. By using rounding tool, the end of the pipe is

- Properly rounded.

- The dimensions of the end are properly formed so that perfect sealing takes place in case of external as well as internal sealing fittings.

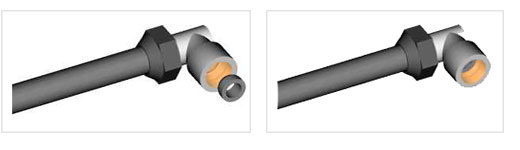

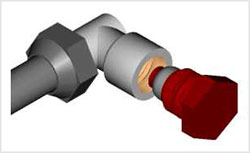

Chamfering of Pipe

It is always essential to chamfer the end of the pipe when pipe is used with brass as well as composite internal sealing fittings. The chamfering of the pipe protects the ‘O’ rings against any damage while pushing the pipe over the fitting.