KiTEC Industries (India) Private Limited has been manufacturing PE-AL-PE Composite Pipes in India since 1996.

Manufacture and marketing competitive World class range of products is the result of continual product Research and Development Manufacturing efficiencies,

and dedication to quality is driving force at KiTEC.

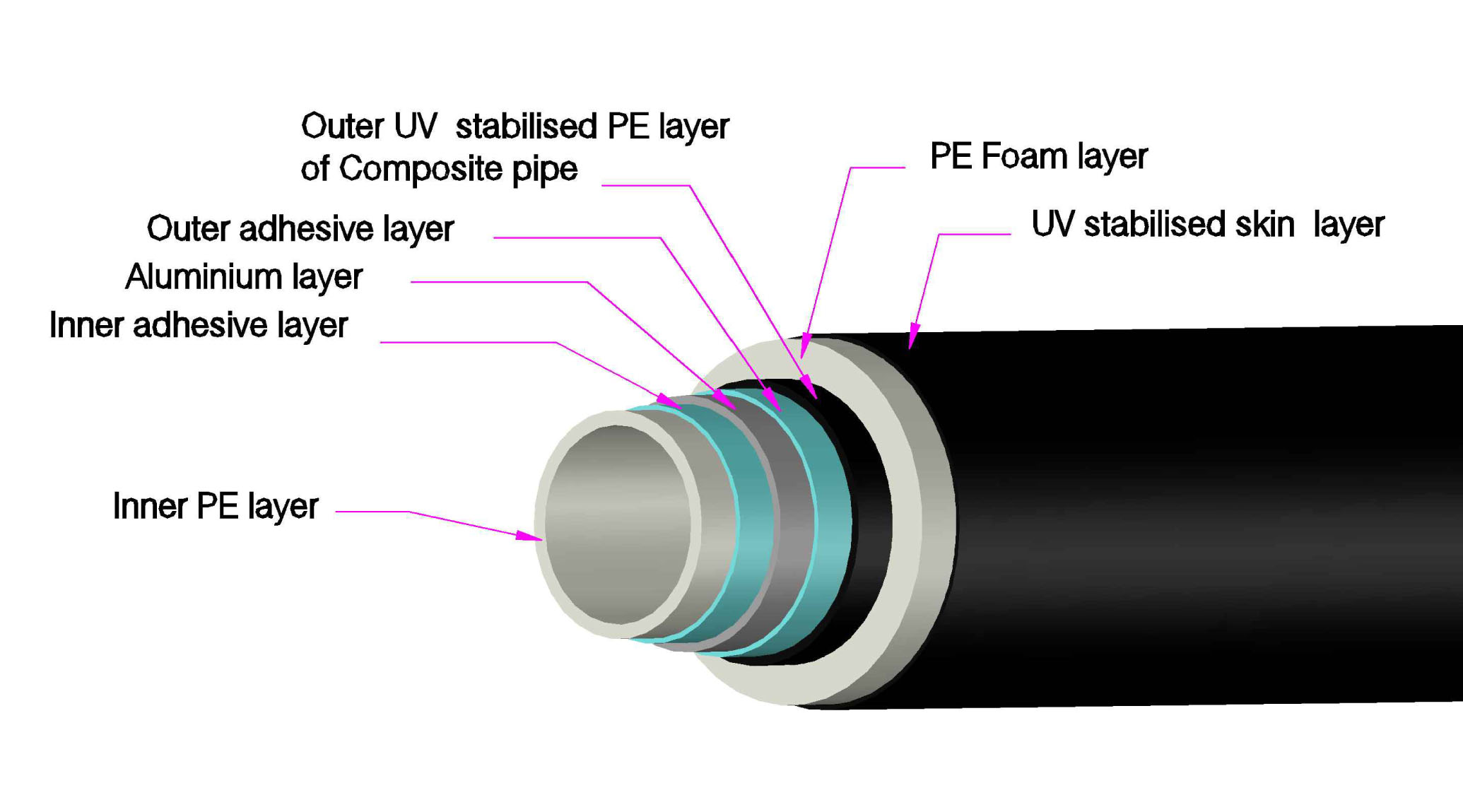

Introduction of insulated pipe

Anti-sun heat preservation Composite Pipe. It is called anti-sun heat preservation Composite Pipe because this product combines anti-sun function and heat preservation effect in one,

-

The Outer UV stabilised layer protects the foam from UV.

-

The Foam Layer having thermal conductivity as low as 0.04 W/(mºK) reduces the heat loss.

-

The inner PE-AL-PE or PE-AL-PEX Composite pipe combines the best features of metal and plastic.

KiTEC pre-insulated Composite pipe are insulated with Closed Cell Foam Insulation with a protective coating of EVA. Closed Cell Foam Insulation (CCF) has been used successfully in HVAC products as a thermal insulation. CCF offers many benefits over fiberglass insulation, which is the typical insulation used in HVAC products today. CCF insulating products are produced by using molten polymeric materials

and non-CFC based blowing agents. When the blowing agent is introduced into the molten polymer, the closed cell air pockets are formed. CCF has a smooth, durable external surface that resists dirt and moisture accumulation, thus reducing the potential for fungal or biological pathogen growth.

Because the surface is tough and resilient, it has a higher degree of puncture resistance when compared to fiberglass products. Even if the insulation surface is punctured, torn or otherwise damaged, the product still resists moisture absorption and microbial growth. CCF does not require an outer moisture vapour barrier or liner because the closed cell structure will not absorb moisture. The surface is easily cleaned if necessary to further resist microbial growth. CCF resists compression due to its rigidity and hence retains its thermal insulating capacity to a greater degree than fiberglass will under compressive forces.

Physical Properties:

Closed Cell Foam insulation (CCF) is a generic term used for Polyethylene based insulation having a closed cell structure. CCF is routinely used in the HVAC and plumbing industry to prevent surface condensation.

Service Temperature:

Polyethylene based materials are classified as thermoplastic. This material begins to soften as the temperature approaches the service temperature limit. The temperature limit is based on the melting point of the polyethylene material used in the insulation. When the service temperature limit is reached, the product becomes plastic and catastrophically melts, shrinks, and slumps.

Thermoplastic materials are very susceptible to temperature spikes even for a short period above their service limit. If the temperature is reduced, the material will not return to its previous shape because the cell walls collapse and hence will no longer perform as an insulator.

The use of Closed Cell Foam Insulation in HVAC appliances is a viable alternative to fiberglass insulation. CCF offers several advantages over fiberglass with regard to moisture absorption and its resistance against microbiological contamination. It is a superior product in its durability when compared to fiberglass. CCF however does not perform as well as fiberglass acoustically. If acoustics are not the primary concern on a project then CCF is an acceptable alternative. CCF costs more than fiberglass however, when one reviews the benefits of CCF as an inhibitor of microbial growth, first cost concerns are usually waived.

Product Range:

| PipeSize |

CoilLength (Mtrs) |

| Insulation Thickness (mm) |

6 |

9 |

13 |

| 1216 KiTEC Composite Pipe |

200 |

200 |

100 |

| 1620 KiTEC Composite Pipe |

200 |

100 |

100 |

| 2025 KiTEC Composite Pipe |

200 |

100 |

100 |

| 2532 KiTEC Composite Pipe |

100 |

100 |

50 |

Technical Data:

| Property |

Value |

Unit |

| Gross density |

30.8 |

kg/m3 |

| Thermal conductivity |

0.04- |

W/(m |

|

Reaction to fire acc.to /EN 13501-1/

|

0.042

E

|

ºK)

-

|

| Maximum Service Temperature acc. To /EN14706/, /EN 14707 |

95 |

°C |

| Minimum Service Temperature |

0 |

°C |

| Water absorption acc. to /EN 13472/ |

WS005 |

|

| Traces quantities of water soluble ions and pH-value acc. to /EN 13468/ |

CL15 - F10

-pH 5.5

|

|

Advantages:

- Pre-insulated for fast installation

- UV resistant Outer Layer

- Available in 50 to 100 meters coil

- Closed cell pre-formed thermal pipe insulation

- Higher density foam for longevity and durability

- Suitable for underground applications

- Low installed cost

- Maximum energy savings

- Resistant to moisture with high vapour resistance-anti-microbial

- Resistant to hydrocarbons and most chemicals

KiTEC Pre-insulated Composite pipe applications:

- Luxury Accommodation Buildings

- Hospitals & Aged Care Facilities

- Hotel & Entertainment

- Hot and cold water supply

- Transportation of chemicals

- Commercial Buildings—Offices etc

- Public Service Facilities & Buildings

- Shopping Centre Complexes

- Multi-Level Unit Housing