KiTEC Composite Piping System

KiTEC Composite Pipes are having pressure rating of 13.8 Kg/Cm2 at 23oC. and 11.0 Kg/Cm2 at 60oC. KiTEC Composite piping system can safely be used for 6 Kg/Cm2 pressure at 80oC working temperature. Short term excursions to 95oC. will not affect the overall performance. Design life span for KiTEC Composite Piping System is in excess of 50 years.

Applications

- Plumbing - Hot & cold

- Air Conditioning

- Solar Heating

- Submersible Pump Piping

- Jet Pump Piping

- Refrigerant Systems

- Radiator Central Heating

- Under Floor Heating

- For Diesel / petrol / Kerosene

- Fuel Oil Lines

- Cable Conduits

- Compressed Air Systems

- Natural Gas Distribution

- Food / Chemical Processing

- Vacuum Systems

- Insecticides Spraying

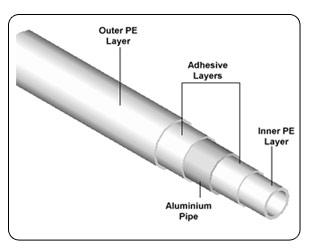

Concept of KiTEC Pipe

Functional properties of various layers are as follows :

Plastic (PE) Layers

PE layers of composite pipe provide all the advantages of plastic pipes such as:- Corrosion resistance

- Chemically inert

- Smooth surface for better flow properties.

Tie Layers

The tie layers have the following functions :- To perfectly bond the metal and plastic.

- Absorb eventual shifting movements between plastic & metal, likely to occur in opposite directions.

- To give the Composite pipe the advantages of a single component pipe.

Aluminium (Metal) Layer

In addition to all the inherent advantages of plastic pipes the inclusion of the metallic pipe gives Composite pipe the qualities of metal, namely :- Absolute tightness.

- Mechanical resistance to deformation.

- Dilation within reasonable limits.

Salient Features

Physical Properties

Malleable

The unique feature of KiTEC is it’s malleability. KiTEC is easily formed into curves, sets by hand and only requires bending springs when forming tight bends down to radius equivalent to 5 times the diameter of pipe. Unlike plastic plumbing pipes, KiTEC permanently holds whatever shape it is formed into and does not need additional clips or brackets to retain the shape of bends or curves.

KiTEC piping systems don’t corrode

Will never pit or develop pin holes from aggressive water leading to premature failure.

No scale build up to reduce flow

Soluble encrustants, such as calcium carbonate do not readily precipitate onto the smooth walls of KiTEC pipes. In addition there are no reduction in flow areas and flow coefficients as the pipes age.

Flame/Smoke Rating

KiTEC pipe has a Flame Spread of 5 and a Smoke Development of 5 as per ULC-S102.2. The ratings meet most building code requirements allowing for the use of KiTEC in high-rise construction as well as in return air plenums and vertical shafts.

Permeation

KiTEC’s aluminum core acts as a permeation barrier against entry of contaminants, and limits oxygen permeation to virtually zero. Permeation is the molecular transport of chemicals, from the soil surrounding the pipe, through the pipe wall and into the fluid being carried within. Permeation may have adverse effects on the piping system, the conveyed fluid or both. KiTEC is widely used for the transmission and distribution of potable water providing a second line of defense for the plumbing system.

UV Resistance and opacity

KiTEC pipes do not have any effect of UV radiation when laid exposed. There is no light transmission.

Thermal Properties

Thermal Strength

KiTEC Composite Pipes are having pressure rating of 13.8 Kg/Cm2 at 23oC. and 11.0 Kg/Cm2 at 60oC. KiTEC Composite piping system can safely be used for 6 Kg/Cm2 pressure at 80oC working temperature. Short term excursions to 95oC will not affect the overall performance. Design life span for KiTEC Composite Piping System is in excess of 50 years. KiTEC Plumbing Pipes are having pressure rating of 12.0 Kg/Cm2 at 23oC. and 6.0 Kg/Cm2 at 65oC. KiTEC Plumbing system can safely be used for 4 Kg/Cm2 pressure at 80oC working temperature.

Thermal Expansion

KiTEC has a low coefficient of linear expansion, similar to copper tubing, and is far superior to alternate plastic pipe. This eliminates the need of installation "offsets" and the concern about abrading pipe due to constant movement as a result of temperature changes. Straight runs are always attainable with KiTEC pipe. Coefficient of Thermal Expansion for KiTEC Pipe is : 25 x 10-6 / oK. Low expansion coefficient is due to tie layer which eliminates the differential expansion of plastic and metal.

Resistance to freezing

In plumbing and water supply applications, KiTEC can withstand multiple multiple cycles of freezing and thawing while under pressure without bursting up to -40O C. temperature. Thawing can be done using a hot air blowgun, hot water injection, and electric blanket or heating cable method. An open flame, torch, or electric current should not be used to thaw the pipe.

Thermal Insulation

KiTEC is having Thermal Conductivity of 0.43 Watt/[m ok.]. KiTEC composite pipes provide an increased resistance to the onset of condensation or pipe sweating in a plumbing application. In case of hot water piping the insulation requirement is only 50% of the same required for conventional metal pipes.

Flow Properties

Higher flow

Because of smooth inside surface KiTEC pipe is scale free and gives higher and consistent flow throughout the service life. Friction drop properties for KiTEC pipes are represented by following graph.

In case of KiTEC fittings, the equivalent length for various fittings is as given in the following table. For calculating the friction drop, add the eqivalent length for highest size of fitting to the length of the pipe. Find out the friction drop from graph.

| Type of fitting | Equivalent length meters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1216 | 1620 | 2025 | 2532 | 3240 | 4050 | 5063 | 6375 | 7590 | 9011 | |

|

Female Branch Tee / Female

Thread Elbow |

1.30 | 1.50 | 1.70 | 1.90 | 2.10 | 2.40 | 2.80 | 3.40 | 3.80 | 4.40 |

| Male/Female Thread Connector | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Equal/Reducing Tee | 2.40 | 3.00 | 3.20 | 3.30 | 3.50 | 3.70 | 3.90 | 4.20 | 4.30 | 4.50 |

| Equal/Reducing Elbow | 2.40 | 3.00 | 3.20 | 3.30 | 3.50 | 3.7 | 3.90 | 4.20 | 4.30 | 4.50 |

| Straight/Reducing Connector | 1.30 | 1.50 | 1.70 | 1.90 | 2.10 | 2.40 | 2.80 | 3.40 | 3.80 | 4.40 |

Chemical Properties

Resists at 20o as well as 60o C.

- Acids

- Alcohol

- Aldehyde

- Ethylene

- Glycol

- Bleach

- Corrosion

- Inhibitors

- Detergents

- Foodstuff

- Petrol

- Diesel

- Fuel oils

- Vegetable/Mineral oils

Resists at ambient temperature

Performance yet to be ascertained at elevated temperatures:

- Beverages

- Insecticides

- Ketones

- Oxidation

- Agents

- Paints

- Salts

- Surfactants/soaps

Chlorine Resistance

- Acids

- Alcohol

- Aldehyde

- Ethylene

- Glycol

- Bleach

- Corrosion

- Inhibitors

- Detergents

- Foodstuff

- Petrol

- Diesel

- Fuel oils

- Vegetable/Mineral oils